Introduction

Nowadays, the fashion and textile sector are one of the most open to developments, changes and innovations. When we look at the production and consumption in the world in this field, it is revealed that there is a large amount of waste products at national and international level with scientific researches, newspaper news, television programs, online meetings and similar studies. With rapidly developing and changing technology, unconscious use of natural resources and the acceleration of consumption accordingly cause environmental problems. The target of this study is to minimize the environmental damage caused by the denim fashion industry and to minimize textile waste. In this context, the concept of sustainable fashion has emerged. With conscious production and consumption, it is aimed to recycle, forward recycle, reintroduce all or several parts of waste. In this study, designs were made in different, modern style instead of unused, worn or outdated denim pants that were inert. New designs were made based on unused, waste-ridden denim trousers and re-entred into the cycle. A qualitative review was conducted through online opinions and publications in academic media and business.

Keywords: Clothing industry, design world, eco-friendly, recycling, waste.

SUSTAINABILITY IN TEXTILE

The textile industry, known as one of the highly polluting industries, has a high rate of chemical load and wastewater and environmental impacts. Other important elements in the textile industry are energy consumption, air pollution, solid waste and odor formation.

When the environmental problems related to the textile and apparel sector are examined; it causes environmental problems in almost every process, starting with the emissions in the production of natural fibers and synthetic fibers and becoming a product. Underneath these problems, liquid wastes, fibers and a significant amount of organic and suspended pollution loads, mostly caused by washing processes, contains htttp://greenpoint.com.tr

These liquid wastes used in the textile industry are usually hot, alkaline and pungently fragrant. Some of the chemicals left in the environment as waste are toxic and can reduce the amount of dissolved oxygen in the waters, threaten water life and reduce overall water quality. In addition, emissions, especially Volatile Organic Compounds (VOCs), are found in excessive noise or odor (https://www.ihkib.org.tr).

Today, many concepts such as "Green Textiles", "Organic Textiles", "Ecological Textiles", "Ecological Design", "Design for The Environment", "Sustainable Design for Sustainability- D4S)" "Life Cycle Assessment - LCA", are included in the sustainability of the textile industry. (İşmal, Yıldırım, 2012).

Although synthetics are seen as the raw material group that causes the most problems in terms of the environment in the textile industry, natural fibers also pose various problems in terms of the environment. Environmental damages caused by pesticides used in the production of cotton, which is the most produced and consumed natural fiber in combination with polyester, a synthetic fiber group (death of beneficial organisms, lead to fish deaths, leakage into groundwater, etc.),genetically modified cotton production and environmental effects caused by the use of chemical-based fertilizers, lead to intense reaction from environmentalists. Although cotton deteriorates in a much shorter time than synthetics in nature, the environmental damage caused by the production process and the use of 29% of pesticides used in Turkey in cotton production damages the "green" image of cotton fiber. (Altun, 2016).

In order to solve this increasing problem in the textile industry, sustainable materials and production methods need to be used. For this purpose, instead of using conventional materials and methods, circular material flow should be adopted and the use of materials obtained by recycling should be preferred (Eser et al., 2016:47).

The concept of "textile ecology" is an important place for sustainability in textiles. When it comes to ecology in textiles, production ecology, human ecology and waste ecology comes to mind. Issues such as the production of the raw material to be used in eco friendly conditions, the selection of the chemicals to be used in processes from products that will not harm the environment, the production of clothes that will not harm human health, the wastes that occur during production and the recycling processes of waste garments that occur after the use of the consumer are very important in terms for sustainability in textiles (Kurtoğlu et al., 2004).

BAYKAN DENIM DESIGN CENTER AND ECO-FRIENDLY DENIM WORKS

Baykan Denim, founded in 1998, is one of the world's leading denim producers. The company produces designs for brands that represent the inspiring interests and lifestyles of people on every continent. Baykan Denim, who strongly believes in the importance of innovation, sustainability and social cohesion, has processed these basic criteria in every product.

Regarding fashion trend tracking; Designers, washing R&D, fabric supply and sales teams visit major markets, fairs and shows around the world. Creative designers Cooperation, fast in the sample house prototipleme and with sales power, Baykan Denim develops 5,000 unique products for its customers every year.

Baykan Denim has Social Suitability Initiative, Social Activity Audit, Organic 100, Ecolabel, re:newcell, ZDHC, Higg Index, Recycled 100, Nordic Ecolabel and BCI certificates. Aiming at innovation, continuous development and development, our company received ISO 9001 and ISO 27001 certificates in 2017 and raised all production and information safety, procedures and processes to internationally accepted standards.

Baykan Denim has gathered all design activities by creating a separate physical area inside its existing building to carry out the design-oriented working structure even more systematically and project-based. With the Design Center structure created with this work, it has been awarded the right to be a Design Center by the Ministry of Industry and Technology as of 17.01.2019. Since 2019, it has carried out and continues to carry out 32 design projects. 6 of these projects are on sustainability.

Baykan Denim produces competitive, high quality and value-added products on time with its global sourcing and comprehensive supply chain network. It provides flexible short delivery time services with regular production and super-fast production to help customers take their success to a higher level. Each step of the productions carried out is carefully monitored to ensure the necessary standards of workmanship, quality and reliability. To do the right thing in line with the wishes of the customers and the decisions to be taken, the operations to be carried out and the products produced are optimized.

Recycling in the clothing industry has started to attract attention in recent years, with retailers in the apparel industry developing partnerships with various organizations to collect used clothing, creating recycling strategies and implementing policies to support post-consumer recycling products. Recycling in the clothing sector can be carried out in two ways, pre-consumer and post-consumer. Reuse, recycling, composting, burning, etc. are possibilities waiting for clothes that have expired. If the consumer decides on the option to give the old garment to the needer or to wear it with minor changes to it, the garment can be worn again, if it is not possible to wear it again, it is considered as recycling. Depending on the criteria such as whether the recycling plant is available, the current condition of the garment, the fiber content of the garment, the extent to which the garment has been used by the consumer, etc. the option to be applied varies.

For customers who want sustainable clothing, applications to attract consumer attention by using the term recycling on the clothing label are a choice that companies care about. Figure 1. Also the garment production cycle applied for recycling is seen.

Figure 1. Recycling Cycle

The main purpose of sustainability is to benefit the products to the maximum extent by extending their life span. As a result of their work, economists and environmentalists have demonstrated the technical and economic requirements of sustainability, as well as the need for waste prevention and recycling.

The aim of Baykan Denim's eco-friendly project is to make the most of the products by extending the life span of the products. However, as a result of the studies economists and environmentalists made, besides the technical and economic requirements of sustainability, as well as the need for waste prevention and recycling, Baykan denim design center has seen it as more of a necessity than a requirement to do our project. Additionally, the reasons that prepare the basis for the formation of this project can be classified as economic, social and environmental.

As in all sectors in the fashion and textile sector, there is a rapid consumption and production problem. In order to prevent this, fashion designers should turn to designing innovative products that slow down consumption with environmental awareness and social responsibility. As a result, it led to the emergence of the concept of sustainability.

Recycling projects have gained great importance in all areas during this period when resources are over-consumed and natural balance is disturbed in the fashion and textile sector. Recycling is also needed in this sector due to the rapid change of fashion in the textile sector and its consumption very quickly. The recovery of second-hand clothing in the waste position has become very important.

In this study, it was tried to draw attention to the issue of sustainability in textiles and fashion. When we think of sustainability, many areas come to mind, but ready-to-wear and fashion have an important place. Production and consumption must be balanced in order to protect the future of our world and to raise environmental awareness. The primary way to be fashionable is to give people environmental awareness.

The fact that the products we carefully select are outdated and obsolete before the end of the season, and the rapid change of tastes also leads to a waste of personal resources. Recycling is an option for these products and has been reused with new designs created.

Denim pants used in recycled designs are converted back into a new product. Thus, the way fashion is produced and consumed is finally transformed into an endless cycle that never ends.

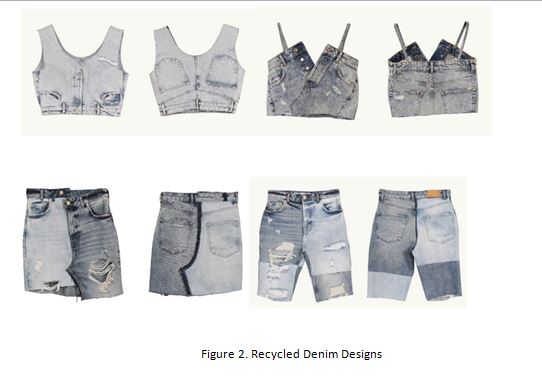

In this study, new product transformation application results are shown with new designs to reduce the environmental burden of denim pants, which are waste after consumer use. In addition, the concept of sustainability was discussed and based on this concept, aging denim pants and other types of fabrics were combined to be transformed into new and modern style designs.

With the great importance of reassessment of clothes, intensive work is being carried out on the recycling of nearly all textile products. For example, if you want to use denim products can contain up to 20 percent recycled cotton fiber. More technological innovations are needed to increase this rate without reducing quality. In the recycling of denim products, unused denim products are broken down until they become fiber. While most of the obtained fibers are used as insulation material, the rest are mixed with unused fibers to produce new fabrics.

Designs have been tried in Illustrator and MYR programs based on previously formed base trouser molds and taking into account the places that are generally deformed on the trousers. In other words, preliminary design drawings of new products that can come out of pants have been made.

Figure 2. Recycled Denim Designs

Mold templates were deformed from manufacturing or cut by placing them on design samples without being used. According to the planting instruction created by the product development department, the products are sewn. The products made are trousers, blouses, skirts.

In the design of trousers; the design is made of two identical trousers. The belts of the two inert trousers were cut to form pockets and legs, while the excess fabrics cut from the mesh part were used in the front and back waist, hips and mesh to complete the upper part for those with narrow trouser legs.

In the design of the blouse; again, a pair of trousers were used that were worn due to the friction of the mesh part. In order to create the model, the inner leg stitch has been removed. The mesh on the front was cut 5 cm below and the front part had all of its seams removed. The left front body is reattached from the disassembled seam marks, which are attached to cover the chest part. The front body is cut in line after completion to be equal to the rear front body. For the straps of the model, rectangular parts were cut from the leg parts of the denim trousers and the hanger was obtained with the help of the apparatus available. The design was completed by sewing the front and back hangers.

When designing the skirt model, it was decided to do it because the knee tear of a pants with self-degradation was too deformed. The model itself has a cord to shrink after the belt. The mesh part of the trousers is cut 20 cm below in order to take the form of the skirt. The inner leg stitches have been removed. Since the front mesh part is too curved, the mesh part is also removed. The front left inner leg and mesh part are joined by bringing it to the top of the right front. The rear right leg was joined by bringing it to the top left back, and the back was completed by sliting from the join between the legs.

Above, it is stated that skirts, trousers and blouses are made of only one design. Designs have changed in other skirt and trouser models. At the same time, every product made is unique.

In accordance with today's fashion, it has been transformed into a new product that can be worn at all times and has been given an aesthetic appearance.

Denim Pants/Trousers Production

Today, denim pants(jeans)are produced the most from denim fabrics. In recent years, denim jackets, skirts, overalls, bags, etc. have become fashionable, but they are not as in demand as denim pants.

The first stage of the garment of denim fabric is the process of cutting the fabric. For the fabric to be cut, the size and size must be determined first. For this purpose, pre-cutting molding is carried out. After the molds are prepared, denim fabrics are cut according to the mold and the cutting process is terminated. Denim pieces cut according to the mold are subjected to planting process.

Seam shares (Figure3) in denim products sewn according to certain models areone of the points to be considered in order to avoid measurement problems. The operation order for a standard denim pants varies very little.

Figure 3. Classic Five Pocket Pants Pattern

The optimum operation and operation order is determined by examining the known or existing operation order. These include, coin pocket hem folding , coin pocket attachment, zipper attachment to fly +fly overlap, combining left placket with body, back pocket emboidery + labeling, back pocket attachment + control, fusing waistband (with iron), beltloop preparation, front pocket-facing lining +front pocket lining, care label attachment , combining the front pocket lining with the body (with binding), body overlock (3 threads), combining the left front body with the left placket with j- stitch, fly closure (right placket mount + crotch closure), fly bartack (1 vertical + 1 horizontal), yoke attachment with overlap stitching, back rise overlap seam, said seam with 5- threads overlock seam, inseam leg (with overlap seam), waistband attachment, belt tip closure, inner label sewing, button hole opening + button + rivet , beltloop + bar tack, hem folding and final control.

The denim pants, which have been sewn, are ready for denim washing. Certain areas on the jeans are named specially.

Figure 4. Front View of Denim Pants

SCOPE AND METHOD OF RESEARCH

Within the scope of this study, denim pants sustainability awareness was formed in the society based on the statistical results of the answers given in line with the results of the survey of denim pants usage frequency, aging time and most deformed places (Figure 5.) and denim pants were provided in two companies producing denim ready-to-wear with the idea that consciousness could be diversified by different methods. In addition, new products are designed in a very modern style using the different types of fabrics we have.

Figure 5. Survey Results

It is aimed to convert denim products within the scope of recycling into new designs in a new and modern style by re-using them for reasons such as deformation, dismantling and aging due to any reason. Thus, stunning clothes are designed in an environmentally friendly, economical, different style. New sources of inspiration, different ideas and movements have been created for designers. Inspired by nature, deformed clothing has become difficult to use or outdated, making it possible to redesign and make wearables. Within the scope of this study, 7 different product designs were made and sustainable denim collection was prepared.

Result

Denim products within the scope of recycling have been converted into new and modern designs by re-using them for reasons such as deformation, dismantling and aging due to any reason. Thus, stunning clothes are designed in an environmentally friendly, economical, different style. New sources of inspiration, different ideas and movements have been created for designers. Inspired by nature, deformed clothing has become difficult to use or outdated, making it possible to redesign and make wearables. As a result of the project, raw material expense was eliminated, washing phase, which is the most time and critical part in denim production, eco-friendly denim designs emerged, washing time of 2 weeks on average compared to washing options in production was eliminated and designers were directed to different issues (sustainability) and areas.

References

Altun, Ş., (2016), Recovery, Environmental and Economic Impacts of Textile Production and Use Wastes, Butler Chamber of Commerce and Industry Report, 26 page.

Work, B., Celik, P., Çay, A., and Akgümüş,D. (2016). Sustainability and Recycling Opportunities in the Textile and Apparel Sector. Textile and Engineer, 23: 101, 43-60.

http://www.butekom.org Environment in Textiles, (2014), "Creating Sample Models for Clean Production in textile finishing sector" Project Technological Evaluation Report, Bursa Textile & Apparel R&D Center. (Accessed On: 30.12.2020)

https://www.ihkib.org.tr Corporate Social Responsibility Status Report in The Textile and Apparel Sector of Turkey, (2012), ITKIB. (Accessed On: 28.12.2020)

İşmal, E. Ö., Yıldırım, L, (2012), Eco-Friendly Approaches in Textile Design, 1. International Fashion and Textile Design Symposium, Akdeniz University, Antalya, 38-42.

Kurtoglu N. Şenol D. (2004). Textile and Ecology Overview, Carcinogen and Allergy-Acting Textile Chemicals. K.S.U. Journal of Science and Engineering, issue:7, p.26-38.

Toksöz, M., Mezarcıöz, S., (2013), Sustainability Concept and Applications in textile sector - Review in terms of Textile Fibers, Textile Technical Journal, 29(347), 118-125.